Allison Transmission will present a broad range of technologies from traditional propulsion solutions to the new Allison eGen Power® electric axles at one of the world’s leading transportation shows.

SÃO PAULO, November 2022 – Allison Transmission, a leading designer and manufacturer of propulsion solutions for conventional and electrified vehicles, and the largest global manufacturer of fully automatic transmissions for medium, heavy commercial, and defense vehicles, will showcase its new electric axles, Allison eGen Power®, at Fenatran 2022 from November 7 to 11 at São Paulo Expo, Stand E218. Allison, a proud sponsor-in-part of Fentatran, will exhibit the new technology alongside its broad range of fully automatic transmission in its larger, centrally-located booth.

Visitors to the Allison booth are invited to explore the eGen Power and Allison’s fully automatic transmissions via an interactive augmented reality experience where they will be able to rotate the products 360° and view internal components.

Technologies to optimize Allison Automatics

One of Allison’s most successful technologies is FuelSense® 2.0, which further reduces fuel consumption in all segments of a vehicle's work cycle. FuelSense 2.0 is ideal for urban applications such as refuse collection, construction and distribution. This innovative technology solution uses a unique set of software and electronic controls to deliver quantifiable fuel savings of up to 6%, all while maintaining the traditional Allison advantages of quality, reliability, durability and productivity.

Through a series of optimizations introduced into Allison's software, the new FuelSense 2.0 with DynActive® Shifting system provides an infinitely variable combination of shifting points. FuelSense 2.0 uses a real-time learning algorithm that determines the optimal balance between fuel economy and performance.

Another advantage of Allison's fully automatic transmissions is its patented torque converter, which efficiently multiplies engine torque and smoothly transfers it to the gearbox. This hydraulically coupled component adds a controlled damping effect that virtually eliminates leaps from the system. The converter also guarantees gear changes without power interruption, increasing average operating speed, productivity and driver comfort.

One of the main differences between Allison's fully automatic transmissions and the recently introduced automated manual transmissions (AMTs) is Allison's patented torque converter. While the manual clutch pedal is gone in an AMT, a mechanical clutch still facilitates the vehicle’s launch. This mechanical clutch will wear and eventually burn out and need traditional maintenance and replacement, which means a vehicle spends more time being repaired and less time on the road. When it comes to starting performance, reliability, acceleration, maneuvering and driver productivity, nothing comes close to Allison Automatics.

Allison Automatics are also available with an integrated retarder. The Allison retarder uses transmission fluid to provide more braking power. The absorbed energy is converted into heat and dissipated through the vehicle's cooling system. Moreover, as there is no mechanical friction or wear on the drivetrain, automatic transmissions offer better control of maintenance costs and longer brake life. Simply put, the retarder provides braking at higher vehicle speed when it is needed most.

eGen Power fully electric axles

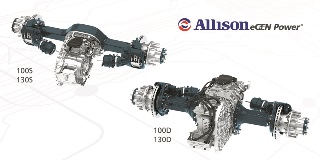

Today, the eGen Power family of products — to be presented digitally at Fenatran — is represented by four models of fully electric, zero-emission axles intended for medium- and heavy-duty commercial vehicles. The eGen Power 100D, introduced in 2020, features two electric motors, each capable of generating over 200 kilowatts of continuous power, with a combined peak power of 650 kW. The 100D also integrates a two-speed gearbox into the center housing, optimizing the e-Axle to allow high ramp-start capability when moving heavy loads while offering higher top speed and superior efficiency. This eGen Power model is capable of supporting a total gross axle weight of up to 10.4 metric tons and includes differential lock functionality.

Subsequently, Allison expanded its dual-motor offering with the eGen Power 130D, introduced in 2021. The 130D is a variant of the 100D, designed for markets where many commercial vehicles require a gross weight of up to 13 metric tons per axle. The 130D retains the same core components, performance and distinctive values as the eGen Power 100D, including the same power characteristics, but with a greater axle weight capacity.

The eGen Power 100S, also announced in 2021, was the first single-motor variant in the eGen Power line of e-Axles. Leveraging core components from the eGen Power 100D such as the motor, inverter and shifting mechanism, the 100S offers exceptional performance characteristics in both 4x2 and 6x4 configurations. Its motor generates 225 kW of continuous power, with peak power of 325 kilowatts and 26,000 newton-meters of torque at the wheels. The 100S expands the existing market for the eGen Power range to include school bus, medium-duty and heavy-duty tractor, and 6x2 and 6x4 articulated trucks applications, including refuse.

The latest product to be introduced to the company's eGen Power family of fully electric axles was the new eGen Power 130S, announced in September this year. Designed to support the required capacity of 13 metric tons of gross weight per axle, it received a single motor capable of generating 225 kW of continuous power, with a peak power of 325 kW and 26,000 newton-meters of torque at the wheels. It features two-speed parallel axles, meeting the demands of applications that demand acceleration capability and highway cruising speed, while maximizing energy recovery through 100% regenerative braking capability.

“We are pleased to present Allison’s latest innovations to the Brazilian market,” said Gabriel Ruggiero, Allison Transmission Regional Director for South America Operations. “Allison takes a global approach to electric vehicle propulsion, because we recognize a variety of products will be needed to address customer needs worldwide and ultimately to deliver on our commitment to provide the most reliable and valued propulsion solutions in the world.”

The eGen Power family of fully electric axles are modular and designed for installation and easy integration into existing vehicle chassis. Allison’s portfolio of e-Axle models has been developed to address the diverse needs of Allison’s customers as they evaluate electric vehicle capabilities to meet the rigorous demands of the commercial vehicle market.

For further information about Allison’s eGen Power family, please visit https://www.allisontransmission.com/ev-solutions/egen-power.